The 99% Accurate Machine Learning Algorithms You Shouldn’t Buy

Machine learning is everywhere , from mobile apps to industrial maintenance. AI algorithms seem to solve almost anything.

But behind the impressive numbers , like 99% accuracy , often hides a disappointing business reality.

So, how can we correctly assess an algorithm’s quality? And why does a high accuracy score not necessarily mean good real-world performance?

The Myth of 99% Accuracy

In many AI-focused Requests for Tender, you’ll often find a familiar line:

“Your algorithm must achieve at least 90% or 99% accuracy.”

While this requirement looks great on paper, it can hide serious flaws.

An algorithm can show nearly perfect accuracy while completely missing the cases that matter most.

A Real Example: Defect Detection on Wind Turbines

At Cornis, we’ve been inspecting wind turbine blades since 2011.

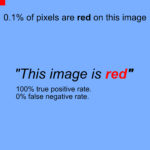

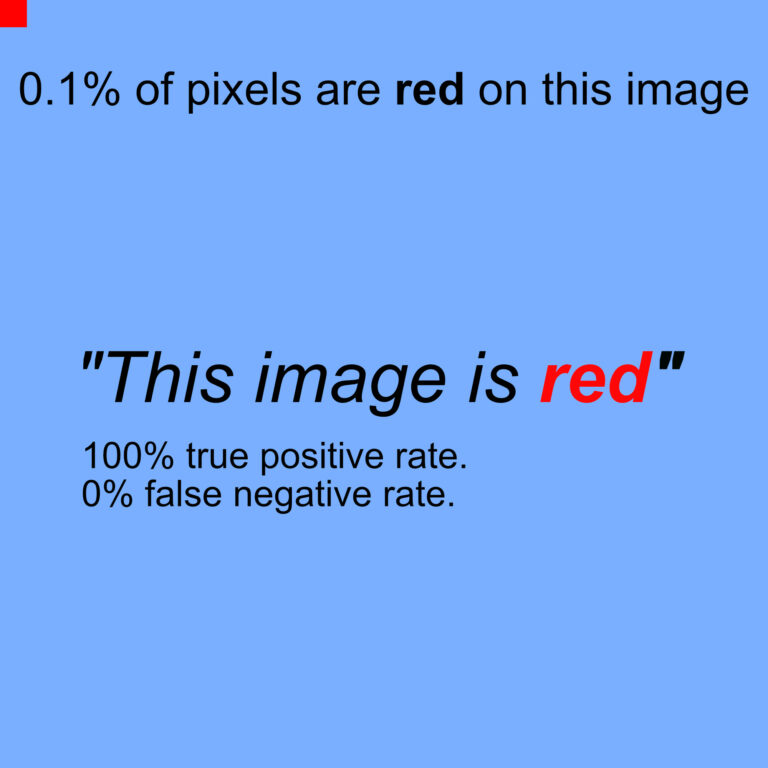

By 2018, our dataset contained 4 million images, but only 6,000 showed a high-criticality defect, that’s just 0.1%.

A naive algorithm predicting no defect at all would reach 99.9% accuracy, yet it would detect zero real issues.

That’s the paradox of false accuracy, an excellent statistical score but zero operational value.

The Metrics That Really Matter

Accuracy alone doesn’t tell the full story.

To properly assess an algorithm, you must look at several complementary metrics:

- True Positive Rate: percentage of actual defects correctly detected

- False Negative Rate: defects missed by the model

- True Negative Rate: defect-free images correctly ignored

- False Positive Rate: images wrongly flagged as defects

These four key indicators provide a more balanced and realistic view of algorithmic performance.

Business Impact: Beyond the Numbers

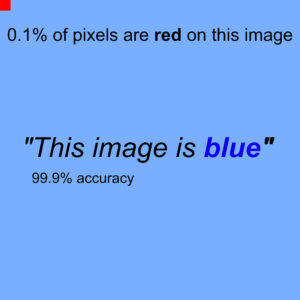

When analyzing a wind turbine, we process about 150,000 images.

Even a model that’s 99% accurate will still produce 1,500 false detections on average.

The true performance indicator isn’t the accuracy score, it’s the time saved during the inspection process.

Depending on where false detections occur, your review time could be cut in half or double instead.

That’s why context matters more than statistics.

The Real Win: AI That Improves Your Process

In 2019, Cornis achieved twice faster turbine inspections thanks to AI.

Interestingly, this model wasn’t close to 99% accuracy in the usual sense.

Its real success came from a balance between precision and operational efficiency.

Don’t be blinded by flashy accuracy numbers.

A machine learning model isn’t valuable because it hits 99%, but because it improves your workflow and business KPIs.

Always demand multiple metrics and focus on real process improvements, not vanity scores.